Detailed Image

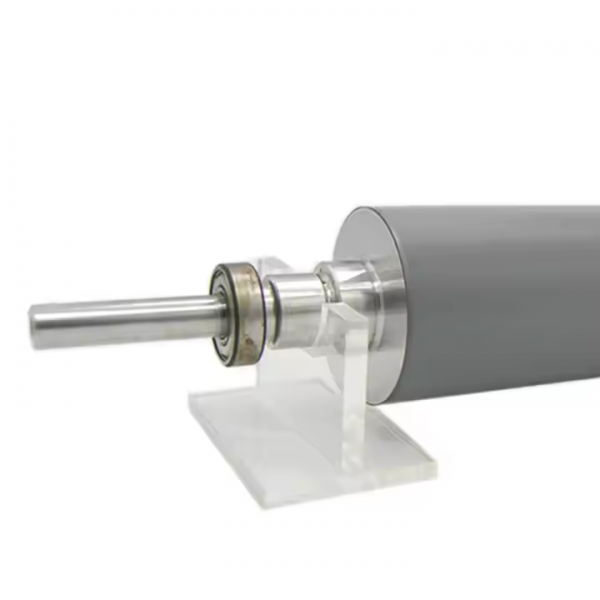

Anilox Roller Flexographic Printer Cylinder Rotogravure For Napkins

Our Advantage 1.Base roller material: 45# steel tube or No5 series aluminum General performance requiremen: 45# steel tube thickness: We can also make the special thickness according to customers requirement. strict inspection procedure of base roller: Incoming inspection including surface roughness,straightness, dynamic balance,cylindricity and so on.

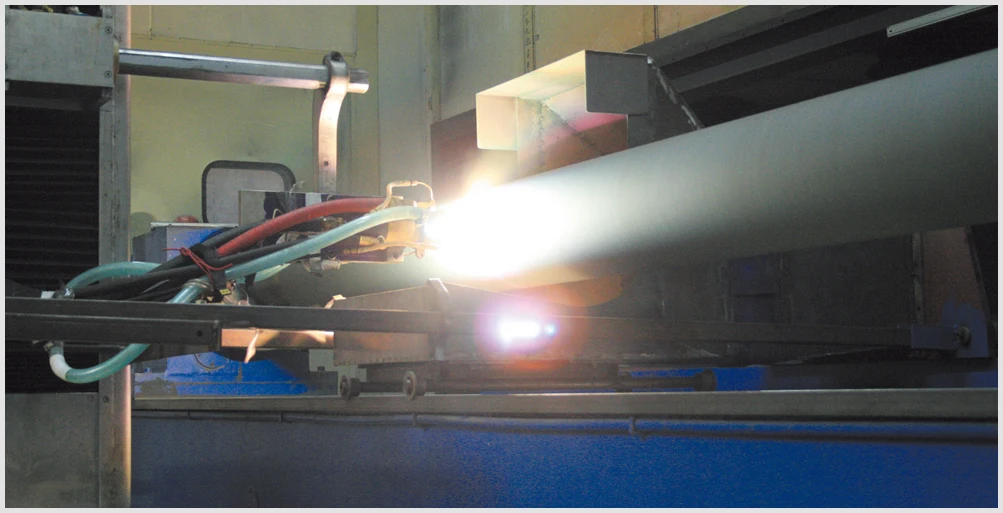

2.Chrome oxide ceramic layer Using the famous plasma spraying machine from Switzerland supplier. The evenness of 80% ceramic powder can be controlled between 15u-35u The hardness of chrome oxide ceramics can reach 1200HV. 3.Antiseptic treatment we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

4.Precise delivery on the inks We make trial engraving before the real engraving. We use the scanner to scan each layer to test the volume of the cell According to the realationship between the LPI and BCM , we can make sure whether the LPI is ok. 5.Quality Control We have the quality control system during the whole production from the very beginning to the end and our principle is to make sure each roller is qualified.

Product Description

|

Item Type

|

Hot Sale Flexo Engraving Ceramic Anilox Roller Printing

|

|

Usage

|

Flexo Machine

|

|

Screen count range

|

30-2000 LPI

|

|

Maximum width

|

5500mm ( with axis)

|

|

Diameter range

|

25-600 mm

|

|

Cell shape

|

Hexagon,Diamond,Tri-heliCal and other special shapes

|

|

MOQ

|

1PC

|

|

Cell Angle

|

60°,45°,30°and other special requirements

|

|

Delivery

|

About 25 working days after received payment

|

|

Payment

|

VISA,T/T,Weston Union and etc.

|

|

Shipping Method

|

By Sea,DHL,Fedex,TNT and etc.

|

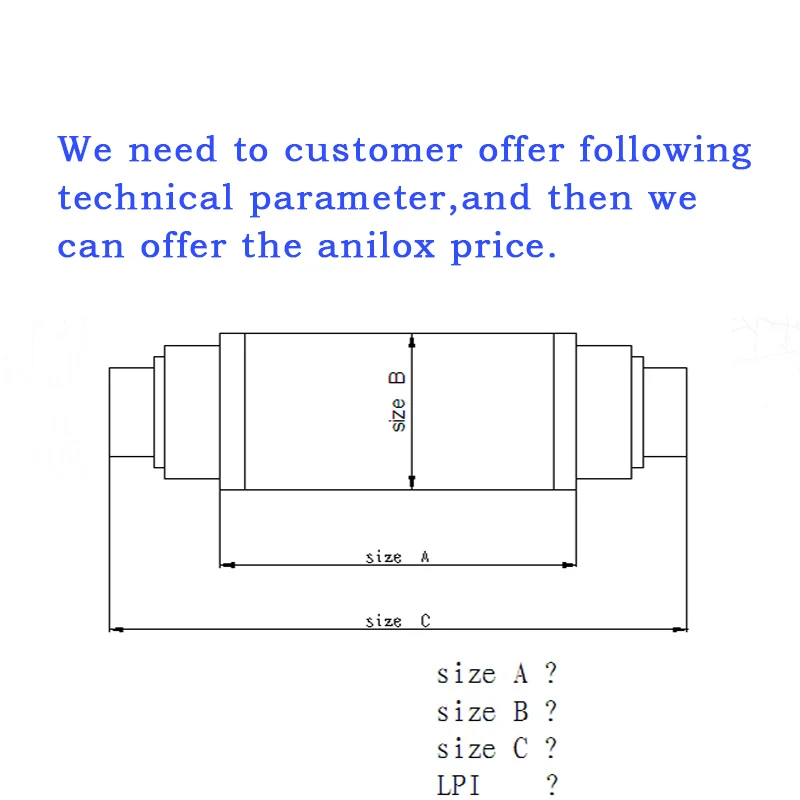

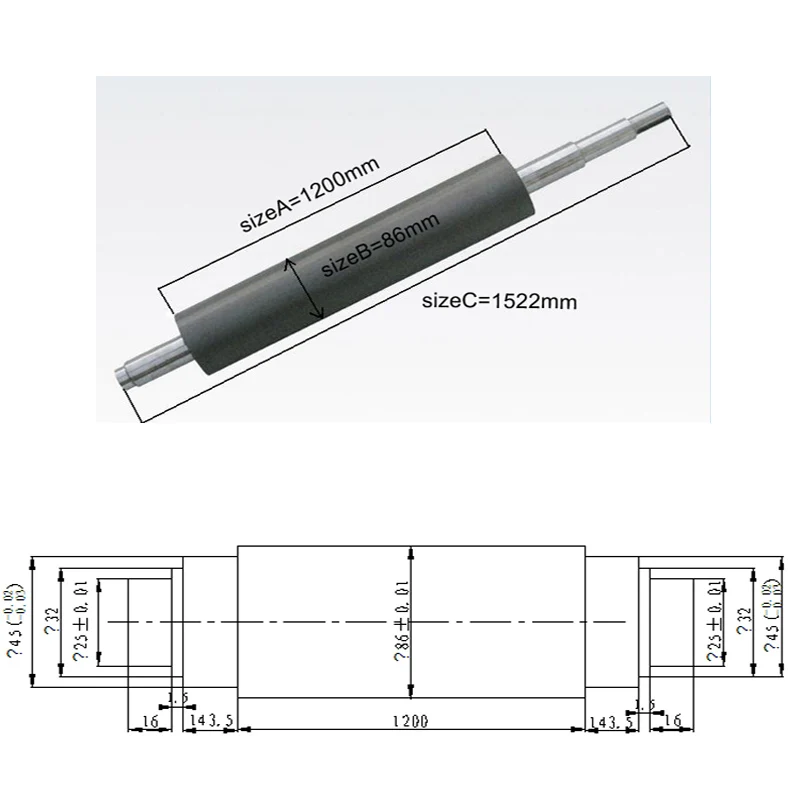

Custom instructions: Please provide customized roller size (diameter, length) and other special requirements,and fax the design drawings to our company.If you do not have the design drawings, please contact our company, the engineer will provide you with professional solutions.

Maintenance of anilox roller The anilox roller is a precision component that needs to be cleaned regularly to prevent ink from solidifying and blocking the anilox holes.Usually divided into two types of cleaning: 1. Steel brush with special cleaning agent. 2. Use ultrasonic cleaning machine for cleaning.

Packaging&Shipping

Package:

Wooden Care Or Carton Package

Shipping:

(1)By Express :2~5working days (Including DHL,UPS,EMS,Fedex)

(2)By Sea:21~45working days

(3)By Air:3~7working days

(4)By Truck:28-33working days

Tips: We will send you a tracking number or BL documents after the goods was shipped .