Industrial Steel Rollers for Packaging Machinery | Heavy-Duty Conveyor Rollers & Custom Solutions

Applications of Steel Rollers

Steel rollers are essential components in numerous industries due to their durability and precision. Key use cases include:

- Manufacturing & Metal Processing: Used in conveyor systems, rolling mills, and sheet metal forming.

- Printing & Packaging: Ensure smooth paper or film feeding in presses and laminators.

- Automotive: Critical for assembly lines, tire production, and part stamping.

- Food Processing: Stainless steel rollers meet hygiene standards for dough rolling, canning, and bottling.

- Construction: Support heavy loads in road rollers and material handling equipment.

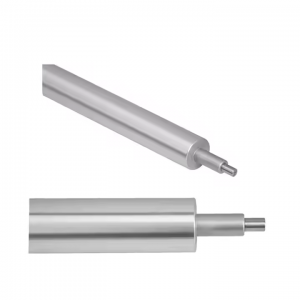

Product Description: Premium Steel Rollers

Our steel rollers are engineered for maximum performance:

- Material: High-grade carbon/alloy steel or stainless steel (corrosion-resistant).

- Surface Finish: Polished, hardened, or coated (chrome, rubber) for wear resistance.

- Dimensions: Standard diameters from 20mm to 500mm; lengths up to 6 meters.

- Load Capacity: Designed to handle 1–50+ tons, depending on specifications.

- Precision: CNC-machined with tolerances as tight as ±0.01mm.

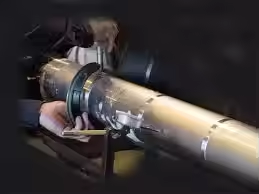

Custom Steel Roller Services

Tailor-made solutions to meet unique operational demands:

- Size Adjustments: Custom diameters, lengths, and shaft configurations.

- Material Upgrades: Stainless steel, heat-treated alloys, or rubber-coated surfaces.

- Special Features: Grooves, flanges, or threaded ends for specific machinery.

- Bulk Orders: Volume discounts for large-scale industrial projects.

Packaging & Shipping

We ensure safe delivery worldwide:

- Packaging: Wooden crates or heavy-duty pallets with anti-rust coatings.

- Documentation: Compliant with international export standards (ISO, CE).

- Shipping Options: Air freight (3–7 days), sea freight (15–45 days), or express couriers.

- Insurance: Available for high-value orders.

FAQ: Steel Rollers

Q1: What’s the lead time for custom steel rollers?

A: Standard orders ship in 2–3 weeks; complex designs may take 4–6 weeks.

Q2: Can I request samples before bulk orders?

A: Yes, sample rollers are available for quality testing.

Q3: How do I maintain steel rollers?

A: Regular cleaning, lubrication, and avoiding overloads extend lifespan.

Q4: Are your rollers compatible with [X] machine brand?

A: Provide specifications, and we’ll ensure seamless integration.

Q5: Do you offer OEM branding?

A: Yes, laser engraving or labels for private branding.

Optimized Keywords: steel rollers, industrial rollers, custom steel rollers, heavy-duty rollers, conveyor rollers, precision rollers, OEM rollers.

CTA: Contact us today for a free quote and elevate your machinery’s efficiency with premium steel rollers!

Wenzhou Runding Embossing Roller Machinery Co., Ltd

Wenzhou Runding Embossing Roller Machinery Co., Ltd is established in March, 1986, specialized in manufacture of all kinds of metal embossing machine, calender machine, mirror roller, hot rolling, cool roller as well as various machinery and customized special equipments, such as embossing, calendering, coiling and slitting machinery.

The roller and machinery products can be applied in plastic, artificial leather, natural leather, paper, chemical fiber, decorative material, apparel fabric, metal sheet (aluminum, steel, painted board, stainless steel etc.), rubber and plastic equipments as well as embossing, calender and treatment on some special material.

Under the great efforts over the past 30 years, RD’s products have successfully penetrated into five continents and all local provinces, with totally over 5,000 new and frequent customers and 2,000 customers in long partnership. Brand of “RD” is the famous brand name of both Zhejiang province and national area.

Runding will provide our customers with the best customized services by communicating with them comprehensively. To achieve the longest-lasting cooperation with customers, we will come up with the most cost-effective solutions, drawing the most detailed design and showing the utmost respect!