Product descriptions from the supplier

Products Description

|

Product Name

|

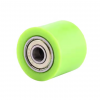

Durable heavy duty Polyurethane Coated Stainless Steel Aluminium Core Wheel PU Rubber Wheel

|

|

|

Functions and Features

|

Abrasion resistant

|

Vastly superior to rubber wheels, plastics wheels and metal wheel

|

|

Oil and solvent resistant

|

Have excellent resistance to oils, solvents, fats, greases and gasoline.

|

|

|

Load bearing capacity

|

Have a higher load-bearing capacity than any conventional rubber.

|

|

|

Tear resistant

|

Tear-strength ranges between 20-50 kg./linear cm, which is far superior to rubber wheels

|

|

|

extremely high flex-life

|

Can be expected to outlast other elastomer materials

|

|

|

Heat and cold resistant

|

Polyurethane wheels can be used to 100°C. At low temperatures, polyurethane wheels can be used to -20°F.

|

|

|

Application

|

Traction wheels for forklift trucks, drive belts, drive wheels for drums, roll cover traction and in automated sorting systems

|

|

Product performance Introduction:

1. Polyurethane wheels have better abrasion and tear resistance than rubber wheels, while offering higher load bearing capacity.

2. Compared to plastic wheels, Polyurethane wheels offer superior impact resistance, while offering excellent wear properties and elastic memory.

3. Polyurethane is available in a broad Shore hardness range, depending of surface, load capacity and preferd rolling conditions the Shore hardness be chosen to fit the application.

4. Polyurethane wheels have replaced metal wheels and cast iron wheels, with benefits such as weight reduction, noise abatement and wear improvements being realized.

2. Compared to plastic wheels, Polyurethane wheels offer superior impact resistance, while offering excellent wear properties and elastic memory.

3. Polyurethane is available in a broad Shore hardness range, depending of surface, load capacity and preferd rolling conditions the Shore hardness be chosen to fit the application.

4. Polyurethane wheels have replaced metal wheels and cast iron wheels, with benefits such as weight reduction, noise abatement and wear improvements being realized.

Chosing for Polyurethane wheels can reduce maintenance and OEM product cost. It provides a cut down in maintenance time and failure costs while you gain the advantages of optimal rolling resistance

Product packaging

Company Profile

Wenzhou Runding Machinery Co., Ltd. is a company focusing on timing pulley and timing belt, PU wheel and PU roller, CNC Parts, committed to doing a good job in precision machine parts, with a strong R & D and production team. After more than 10 years of efforts, it has become a leading manufacturer and supplier of precision machine parts with complete models and excellent quality. Let the customer obtain the high quality Factory automation components not to be difficult.

Our Advantages

1. More than 10 years of professional experience.

2. 100% Strict inspection and high quality with reasonable price.

3. One pcs can also be customized by OEM.

4. Delivery time is short.Samples will be shipped in 2-5 days

2. 100% Strict inspection and high quality with reasonable price.

3. One pcs can also be customized by OEM.

4. Delivery time is short.Samples will be shipped in 2-5 days

5. A transaction, a permanent service.