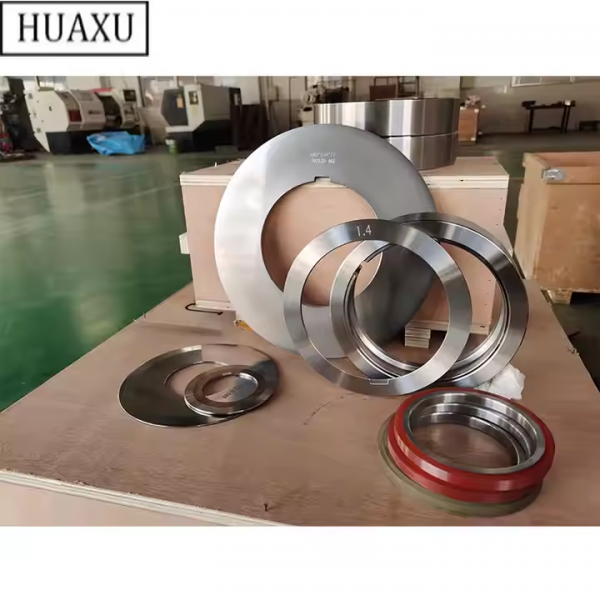

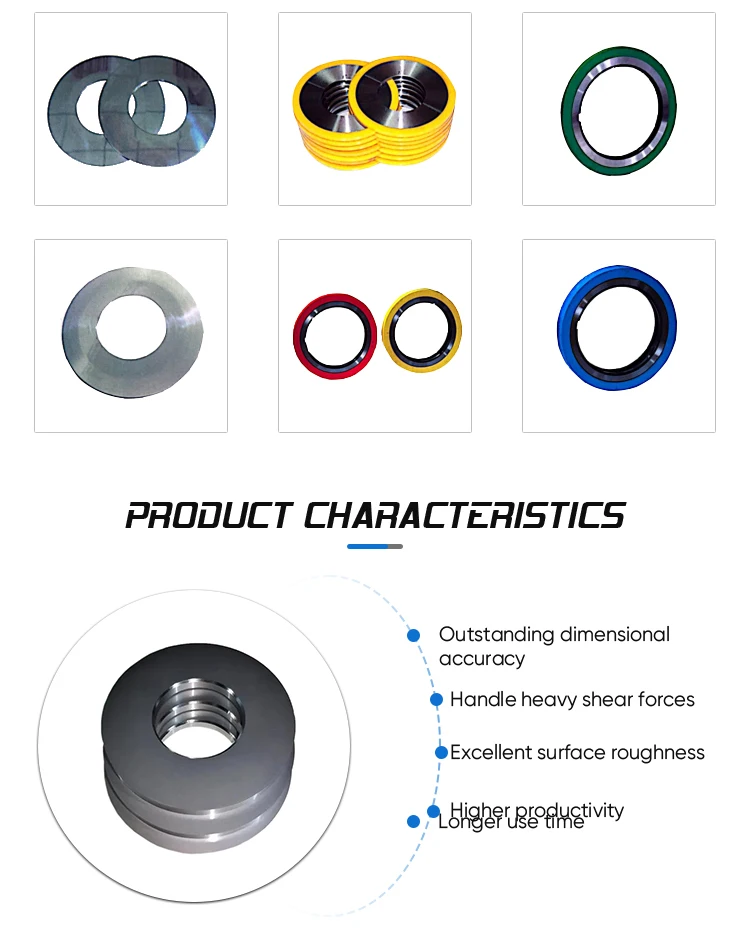

Cold Rolled Steel Galvanized Sheet Metal Mini Slitter Rewinder Coil Slitting Line Machine Hss Circular Blade for Metal Cutting

Runding blade will use its rich experience and advanced processing equipment to provide you with high-quality cutting tools and accessories.

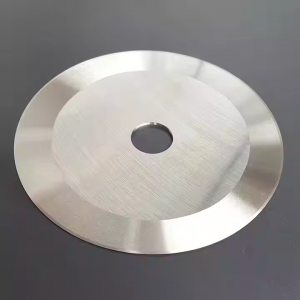

Sash knife is mainly used for metal sash production processing line, blade raw materials are made of high-speed cutting tool steel SKD, SLD,SKH and other precision machining. Especially suitable for all kinds of cold and hot rolled steel plate, pickling plate, silicon steel plate, stainless steel, silicon steel sheet, steel strip and other high-speed cutting strip production operations. Slitting blade is the most important part of the production process, the accuracy of the slitting knife is very high, for the blade plane we use precision grinding machine, after forging, machining, heat treatment, and then special grinding, and strict quality management to ensure that the parallelism of all finished products are within 0.003mm.

Superior quality

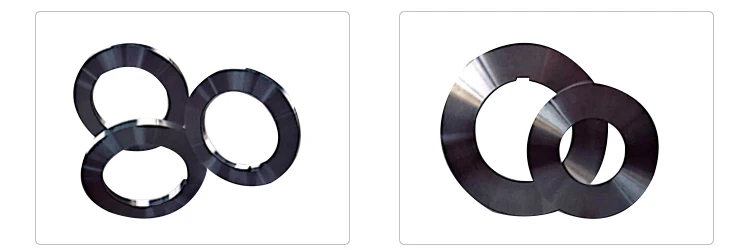

The blades are made of 9CrSi Cr12MoV and other materials,with good toughness, highhardness and excellent

Quality technology

The vacuum quenching process greatly improves the hardness and toughness of the blade and improves the service time of the blade

Higher accuracy

Adopt a varietyof professional Imported CNC machine tools And high precision cutting, Ensure the sharpness and accuracy of the cutting edge

Strict detection

The company uses optical, X-ray flaw detection and other technologies for product testing, and each product can be stored after passing the test.

SKD-11 tooling steel

SKD-11 is applicable to cold or hot rolling plate,stainless steel,galvanized plate,aluminium cheot steel nlate etc”SKD-11 is of toughness, friction resistance stc. SKD-11 is of toughness friction resistance stc.

|

SKD-11

(Cr,Mo,V.)

|

Steel Type

|

Sheet thickness

|

Standard hardness

|

|

Aluminium or copper

|

sheet 0.3m/mt—3.2t/mt

|

HRC60–61

|

|

|

Stainless steel

|

0.1m/mt—1.2t/mt

|

HRC60–61

|

|

|

Stainless steel

|

1.2m/mt—2.0tmt

|

HRC58–59

|

|

|

Cold or hot rolled plate

|

0.1m/mt—2.0t/mt

|

HRC60–61

|

|

|

Cold or hot rolled plate

|

2.0m/mt—3.2t/mt

|

HRC58–59

|

H13(H13K) hot work die steel

High temperature strength and edge balance is good. Suitable for hot rolled plate, pickling plate, stainless steel, medium thick plate, ship plate and other shear slabbing.

|

H13K (4Cr5MoSiV1W)

|

Material of steel

|

Sheet thickness

|

Standard hardness

|

|

hot rolled

|

2m/mt—4t/mt

|

HRC57–58

|

|

|

hot rolled

|

5m/mt—7t/mt

|

HRC55–56

|

|

|

H13

(4Cr5MoSiV1)

|

hot rolled

|

8m/mt—12t/mt

|

HRC53–54

|

|

hot rolled

|

15m/mt—20/mt

|

HRC50–51

|

SLD

SLD features very good cutting ability and it is almost twice better than SKD-11 in terms oftoughness and wear resistance. This material is more fit for knives cutting Stainless Steel and HighCarbon & High Manganese steel.

|

SLD

(7Cr7Mo3V2Si)

|

Material of steel Sheet

|

Sheet thickness

|

Standard hardness

|

|

Stainless steel

|

0.1m/mt—1.2t/mt

|

HRC61–62

|

|

|

Stainless steel

|

1.2m/mt—2.0tmt

|

HRC59–61

|

|

|

High-carbon and manganese steel

|

0.3m/mt—1.5t/mt

|

HRC62–63

|

|

|

High-carbon and manganese steel

|

1.5m/mt—2.5t/mt

|

HRC60–61

|

|

|

High-carbon and manganese steel

|

2.5m/mt—3.5U/mt

|

HRC58–59

|

The common materials of the separator are SKD-61(4Cr5MoSiV1), 40CrMo Cr12, etc. SKD-61 is a commonly used material. SKD-61 has a good balance of high temperature strength and toughness, which is mainly used for the completion of the receiving work of the sheet strip, so that each width of the steel strip can maintain a certain gap without colliding with each other. In the process of manufacturing the separator, we have heat treatment leveling, fine grinding, polishing, chromium plating (0.05m/mt hard chromium) and then polishing to make its surface smooth and flat, high wear resistance and the separated steel strip is neat and smooth.

Tolerance on blade and sleeve

|

Unit Size: mm

Untmm Unless otherwise specfied

|

|||

|

Precision

|

High precision

|

||

|

Thickness

|

E

|

±0.003

|

±0.002

|

|

Parallelism

|

0.003

|

0.002

|

|

|

Roughness

|

0.2Ra

|

0.08-0.12Ra

|

|

|

O.D.

|

D

|

±0.05

|

±0.025

|

|

ID.

|

d

|

±0.05-0.09

|

±0.03-0.05

|

|

Perpendicularity

|

0.01 (maximum)

|

||

Tolerance on parallelism

|

Thickness

|

Thickness

|

Thickness

|

|

1-3 mm

|

0.08-0.15

|

0.04-0.06

|

|

3-6 mm

|

0.03-0.07

|

0.02-0.04

|

|

6-10 mm

|

002-004

|

0.01-0.03

|

|

>10mm

|

0.005-0.01

|

0.002-0.005

|

Parallelism tolerance to be determined by diameter and thickness

Q:How long for the delivery time?

A:Normally 3-5days if product are in stock for those we do not have stock then it will ake 2-4 weeksbut it also can be negotiated based on order qty and production schedule.

Q: How can you guarantee the production quality?

A: Our production is based on lS0 9001, We have 15 years experience of Qc team and strictlyquality control system in our production process. We have 4 times inspection for each finishedproduct before package.

Q:Can I get my logo on the blade?

A:Yes, we have laser machines that can help you carve your mark on the blade and keep it secret for you.

Q: Can l get my owner Logo on the blade?

A: Yes, we have laser machine to make your owner design Logo and keep it secret.

Q: Can l get one sample before l order?

A: Yes, for standard blade we will send you one sample for quality check. For customized bladewe will only start mass production of your approval of sample quality.