Product descriptions from the supplier

Product Description

Specification

|

Item

|

Data

|

|

Condition

|

New

|

|

Warranty

|

1 Year

|

|

Weight (KG)

|

25

|

|

Showroom Location

|

None

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Place of Origin

|

Jiangsu, China

|

|

Brand Name

|

Relaser

|

|

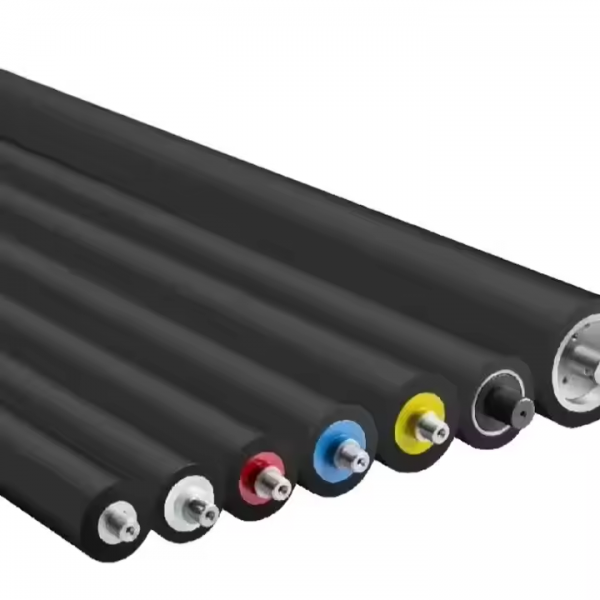

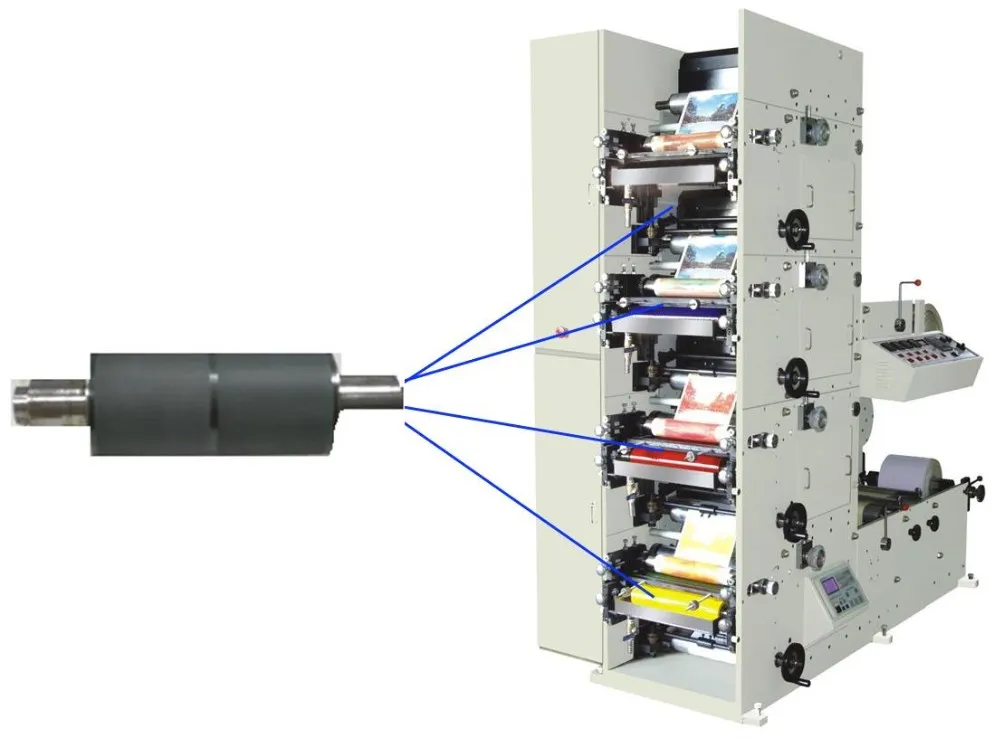

Type

|

Anilox Roller

|

|

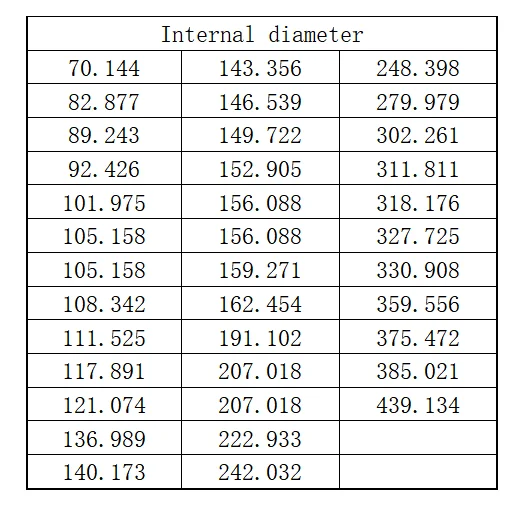

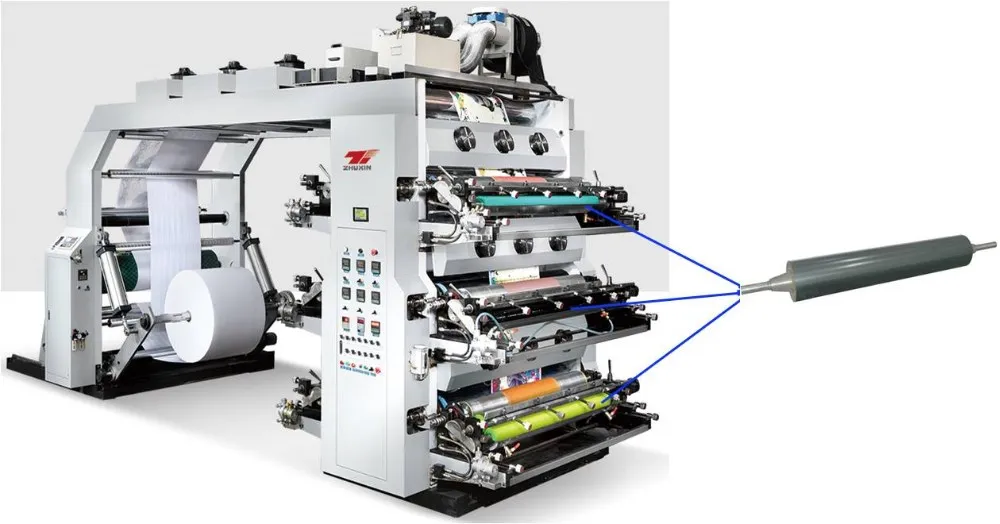

Use

|

all brand flexo and offset printing machine

|

|

Printing Type

|

flexo and offset printing machine

|

|

Material base roller

|

steel or aluminum

|

|

Maxinum width

|

5500mm (with axis)

|

|

Diameter range

|

40-600mm

|

|

LPI

|

20-1800

|

|

Cell shape

|

Diamond 45, Hexa 60, Line, etc.

|

|

Package

|

Wooden box

|

|

MOQ

|

1 Piece

|

|

Usage

|

For label&sticker printing, packaging printing, corrugated cardboard printing and offset printing, etc.

|

Our workshop and facilities

Application

Packing & Delivery

Company Profile

Runding Material Engineering is located in the national high-tech zone of Changzhou, Jiangsu Province. It is a high-tech enterprise that dedicates to the precision special ceramics, processing and manufacturing. Relaser has a strong in-house R&D team and a complete ceramic roller production line, with over 10 patents in the field of invention and utility model patents.

Runding mainly manufactures ceramic anilox rollers that are suitable for the patent technology of special aviation ceramic process formula and special ceramic powder laser compound coating. The company applies plasma thermal spraying process, high-precision grinding, mirror polishing, and high-speed, high-precision laser direct carving to manufacture high hardness ceramic layer. The product has excellent wear resistance, and can reach ordinary chrome-plating roll several times of life. It is widely used in lithium battery diaphragm ceramic coating, flexographic printing, gravure printing, coating and other fields.

Exhibition

You can talk to us during the following exhibition if you’d want to learn more about us.

Our Advantages

1. We’re a manufacturer. Compared to traders, we provide lower costs, faster delivery, and higher quality guarantees. You can monitor the processing progress and testing results of the products over the Internet.

2. We are China’s developing leader in ceramic anilox rollers. Our ceramic anilox rollers are used by Xi’an Aerospace-Huayang Mechanical & Electrical Equipment Co., Ltd, China’s largest satellite flexo printing machinery factory; Egofa Flexopacking Machinery Co., Ltd., China’s largest unit flexo printing machinery factory; and Weifang Donghang Graphic Technology Inc. In the lithium battery coating sector, we are the largest provider of ceramic anilox rollers to CATL, the world’s largest lithium battery manufacturer.

3. Sufficient production capacity leads to speedier delivery times. We currently have 16 laser engraving machines, with an annual increase of 6.

4. Exquisite processing technology results in a ceramic coating with improved hardness and bonding force, a longer service life of the anilox roller, and increased corrosion resistance.

5. Our ceramic anilox roller’s ink loading is more accurate thanks to the sophisticated laser engraving machine and careful inspection procedure.

FAQ

1. Who are we?

We are located in Jiangsu, China, and started exporting in 2018 to the domestic market (60.00%), Southeast Asia (15.00%), South Asia (5.00%), South America (5.00%), Oceania (5.00%), Africa (5.00%), and North America (5.00%). Our organization has a total of approximately 50 employees.

2. How can we ensure quality?

Pre-production samples are always provided before mass production, and final inspection occurs prior to shipment.

3. What can you purchase from us?

Laser engraved ceramic anilox roller/sleeve, Anilox roller cleaner, Laser cleaning machine, Ultrasonic cleaning machine, Laser engraving machine, Mirror roller, Dermatoglyph roller, etc.

We are located in Jiangsu, China, and started exporting in 2018 to the domestic market (60.00%), Southeast Asia (15.00%), South Asia (5.00%), South America (5.00%), Oceania (5.00%), Africa (5.00%), and North America (5.00%). Our organization has a total of approximately 50 employees.

2. How can we ensure quality?

Pre-production samples are always provided before mass production, and final inspection occurs prior to shipment.

3. What can you purchase from us?

Laser engraved ceramic anilox roller/sleeve, Anilox roller cleaner, Laser cleaning machine, Ultrasonic cleaning machine, Laser engraving machine, Mirror roller, Dermatoglyph roller, etc.

4. Why should you buy from us rather than other suppliers?

We are a high-tech company that specializes in precise specific ceramics, including processing and production.We have a complete ceramic roller production line, as well as excellent technical and technological research and development capabilities.We have more than ten patents.We can offer you not only a competitive price, but also the highest quality service.

5. How long is the lead time?

It usually takes 20 days to construct the roller/sleeve, but this varies depending on the quantity and customer requirements.

We are a high-tech company that specializes in precise specific ceramics, including processing and production.We have a complete ceramic roller production line, as well as excellent technical and technological research and development capabilities.We have more than ten patents.We can offer you not only a competitive price, but also the highest quality service.

5. How long is the lead time?

It usually takes 20 days to construct the roller/sleeve, but this varies depending on the quantity and customer requirements.