Products Description

|

Product Name

|

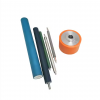

Custom Heavy-Duty Rubber Coated Wheel Roller Silicone PU Layer with Steel Stainless Steel Aluminium Core Guide Roller

|

|

|

Functions and Features

|

Abrasion resistant

|

Vastly superior to rubber wheels, plastics wheels and metal wheel

|

|

Oil and solvent resistant

|

Have excellent resistance to oils, solvents, fats, greases and gasoline.

|

|

|

Load bearing capacity

|

Have a higher load-bearing capacity than any conventional rubber.

|

|

|

Tear resistant

|

Tear-strength ranges between 20-50 kg./linear cm, which is far superior to rubber wheels

|

|

|

extremely high flex-life

|

Can be expected to outlast other elastomer materials

|

|

|

Heat and cold resistant

|

Polyurethane wheels can be used to 100°C. At low temperatures, polyurethane wheels can be used to -20°F.

|

|

|

Application

|

It is used for the protection of important parts such as machine, Auto parts,door and window,It has the cushioning and damping effect

|

|

Roller are circular or cylindrical objects that rotate on an axle to facilitate motion. Roller can be specialized for different terrains and applications, from machinery to vehicles and construction equipment.

Roller wheels are made from a variety of materials including rubber, polyurethane (PU), nylon, phenol, polycarbonate, and elastomers. Each material offers unique properties such as chemical resistance, temperature tolerance, and load-bearing

capabilities.

capabilities.

Product performance Introduction:

1. Polyurethane parts have better abrasion and tear resistance , while offering better buffering.

2. Compared to plastic, Polyurethane bumpers offer superior impact resistance, while offering excellent wear properties and elastic memory.

3. Polyurethane bumpers is available in a broad Shore hardness range, depending of surface, load capacity and preferd rolling conditions the Shore hardness be chosen to fit the application.

4. Polyurethane buffers have replaced metal and plastic, with benefits such as weight reduction, noise abatement and wear improvements being realized.

2. Compared to plastic, Polyurethane bumpers offer superior impact resistance, while offering excellent wear properties and elastic memory.

3. Polyurethane bumpers is available in a broad Shore hardness range, depending of surface, load capacity and preferd rolling conditions the Shore hardness be chosen to fit the application.

4. Polyurethane buffers have replaced metal and plastic, with benefits such as weight reduction, noise abatement and wear improvements being realized.

Chosing for Polyurethane bumpers can reduce maintenance and OEM product cost. It provides a cut down in maintenance time and failure costs while you gain the advantages of optimal rolling resistance

Details Images

Product packaging

Our Advantages

1. More than 10 years of professional experience.

2. 100% Strict inspection and high quality with reasonable price.

3. One pcs can also be customized by OEM.

4. Delivery time is short.Samples will be shipped in 2-5 days

2. 100% Strict inspection and high quality with reasonable price.

3. One pcs can also be customized by OEM.

4. Delivery time is short.Samples will be shipped in 2-5 days

5. A transaction, a permanent service.

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer, we have factory.

Q.OEM/ODM accepted?

A:Customization is very welcome. One can also be customized,Please attach the detailed information of the drawing (dimensions, surface treatment, material requirements, etc.)

Q: Do you provide samples ?

A: Yes, We can provide samples, but you need to pay the freight.

A: We are manufacturer, we have factory.

Q.OEM/ODM accepted?

A:Customization is very welcome. One can also be customized,Please attach the detailed information of the drawing (dimensions, surface treatment, material requirements, etc.)

Q: How long is your delivery time?

A: Generally it is 2-5 days if the goods are in stock. or it is 5-15 days if the goods are not in stock, it is according to quantity.Q: How is quality ensured?

A: All our processes strictly adhere to ISO9001:2008 procedures, we have strict quality control from producing to delivery,100% inspection by professional testing center. Small samples could be provided to you for testing.

A: Generally it is 2-5 days if the goods are in stock. or it is 5-15 days if the goods are not in stock, it is according to quantity.Q: How is quality ensured?

A: All our processes strictly adhere to ISO9001:2008 procedures, we have strict quality control from producing to delivery,100% inspection by professional testing center. Small samples could be provided to you for testing.

Q: Do you provide samples ?

A: Yes, We can provide samples, but you need to pay the freight.

Q:What is your payment method?

A: We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

A: We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.