Products Overview

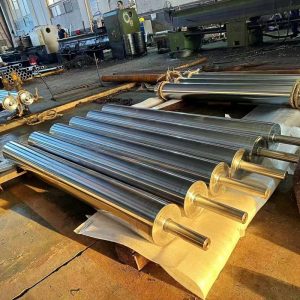

Custom carbon fiber roller/CFRP roller/ carbon fiber roll/ carbon fiber cylinder/ carbon fiber tube

As a precision roller manufacturer, Futian Roller can produce custom carbon fiber roller according to customer’s requirements and drawings, including carbon fiber idler, carbon fiber converting roller, anti-sticking roller, mirror finished carbon fiber roller, etc.

We own ISO 9001:2015 certificate, and we have close cooperation with many famous companies such as Hewlett Packard, EFI, RPA technology, etc.

|

Production type

|

Custom OEM、ODM production

|

|||

|

Material

|

1K/3K carbon fiber, 200g/240g carbon fiber,T300,T700,T800,M30,M46

|

|||

|

Also Named As

|

Carbon fiber roll, CFRP roller, carbon fiber tube, carbon fiber shaft, carbon fiber cylinder, carbon fiber

pipe

|

|||

|

Surface treatment/finishing

|

painting, ceramic coating, tungsten carbide coating, rubber coating, etc

|

|||

|

Diameter

|

As per drawings, Max.1,500mm

|

|||

|

Length

|

As per drawings, Max.14,000mm

|

|||

|

Machining Capacity

|

>1,000pcs monthly

|

|||

|

Inspection

|

Run-out, cylindricity, dynamic balance, etc

|

|||

|

One-Shop Solution

|

Manufacturer&Trading

|

|||

|

Video outgoing-inspection

|

Provided

|

|||

|

Package

|

carton box, plywood box

|

|||

|

Application

|

Non-woven Industry, printing industry, textile industry, paper-making, film manufacturing, copper &

aluminum foil, battery, aviation, etc

|

|||

|

Other products

|

||||

Quality&ISO9001:2015 Certificate

QUALITY CONTROL

* Accept SGS and other third party’s in-site inspection if necessary.

* Provide inspection report for each CTQ and critical part before delivery.

* Confirm the DFM with customer before sample production.

* Provide 8D report and CAR to client in case quality issue happens.

* Have regular maintenance schedule for all measuring tools.

* Strict controls and checkups are conducted on a regular basis.

* In addition, our concerning is not only part itself but also material localization, documentation of production and reasonable design of packaging for long distance transportation.

* Provide inspection report for each CTQ and critical part before delivery.

* Confirm the DFM with customer before sample production.

* Provide 8D report and CAR to client in case quality issue happens.

* Have regular maintenance schedule for all measuring tools.

* Strict controls and checkups are conducted on a regular basis.

* In addition, our concerning is not only part itself but also material localization, documentation of production and reasonable design of packaging for long distance transportation.

INSPECTIONS

Quality runs through the whole process from material to delivery.

We provide inspection report for each roller before shipment. The below sample reports are for your reference.

Runout inspection

Surface roughness inspection

Package&Delivery

We attach great importance to packaging of carbon fiber rollers. Well-designed packaging can protect our products from damage or rust.

Our Projects

non-stick carbon fiber roller

custom carbon fiber roller for non-woven industry

precision carbon fiber roll for paper-making

customized carbon fiber roll for European customer

cooperation with you.

FAQ

Q1:Do you have the products in stock?

A1:No. All rollers are to be produced according to your drawing and requirements.

Q2:Can I get some samples?

A2:We are honored to offer you samples for quality check.

Q3:What’s the delivery time?

A3:It usually takes about 30 days to produce an order. But the exact delivery time might be different for different orders or at different time.

Q4:Are you trading company or manufacturer?

A4: We are factory with license of import & export.

Q5:How does your factory do regarding to quality control?

A5:Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be carefully inspected before it’s packed for shipment.