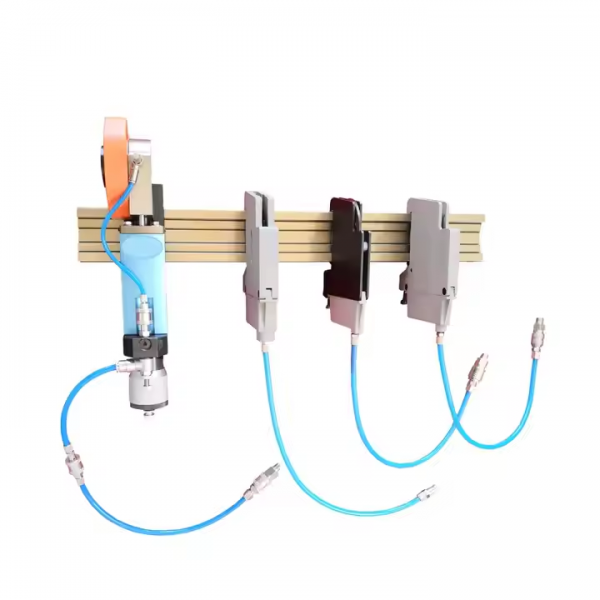

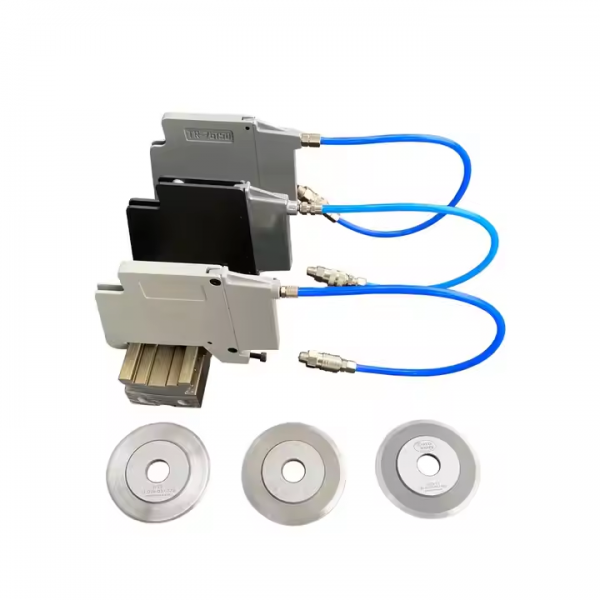

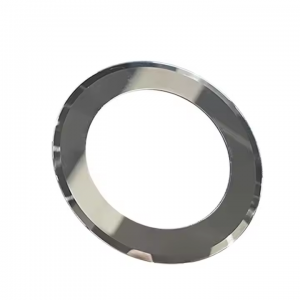

Industrial Fabric Roll Holder with Pneumatic Blade Cutter Features Circular Slitting Machine Blades Slitting machine parts

|

THE PRODUCE NAME

|

PNEUMATIC TOOL HOLDER

|

|

MATERIAL

|

9CrSi SKD-11 CR12MOV 65Mn D2 LD W6Mo5Cr4V2 ETC

|

|

THE SHAPE OF

|

CAN BE CUSTOMIZED BY CUSTOMERS

|

|

THE TIME OF DELIVERY

|

5-10 WORKDAYS

|

|

THE CUTTING OBJECT

|

PAPER(HIGH-GRADE PAPER , DUST-FREE PAPER, FINE GRAIN PAPER,KRAFT PAPER,WALLPAPER,ADHESIVEPAPER,ETC.)

|

Intelligent slitting knife series:

Using the most advanced knob operating system, one-button control, intelligent air pressure path design, technology and use more appreciated, products are widely used in paper, fiber, nonwoven fabrics, non-woven fabrics, melt-blown cloth, film, packaging products, medical products, electronic industrial materials, self-adhesive, composite materials, lithium batteries, copper, aluminum metal coils, etc. Slitting, slitting, sectioning, trimming, pressing cutting, shearing, cutting, sliding cutting, cutting easy to break, easy to tear and other processes. The blade installed in the slitting tool frame is produced by the professional precision tool factory of Ouwei Machinery. After the Longride LCQ vacuum quenching process, the edge and plane of the blade are precision grinding. The advantages of the blade are: high precision, good toughness, ordinary product hardness in HRC58-62, and high product hardness in HRA86, which can be easily used in high-speed machine and ultra-high-speed machine equipment.

1: Sharp blade, smooth cutting

The knife edge is sharp and the knife body is free of burrs, making the cutting surface beautiful

Reasonable cutting Angle increases the performance of the blade to a certain extent

Reduce the wear and tear of the blade and reduce the use cost of the blade.

2: Multiple quenching hardness uniformity

The hardness is uniform after repeated hardening by vacuum man treatment Not easy to deform, improve the service life and stability of the knife.

3: High quality material is durable

The use of high-quality imported materials at home and abroad, complete raw materials

9crsi, Cr12MoV, SKD-11, LD,D2 and other high-quality abrasive steel

good materials can reduce the loss of blades, reduce processing costs

4: Professional non-standard customization

Because focus so professional

Focus on manufacturing all kinds of mechanical blades support non-standard customization

Drawing to sample can be customized professional services

Before-sale service:

(1) Your inquiry related to our products will be replied in 24 hours.

(2) Experienced staffs to answer all your enquires in fluent English.

(3) We makethe OEM and ODM service for more than 6 years. And the Paypal accepted,

(4) Protection of your sales area, ideas of design and all your private information.

(5) No matter big order or small order , we will provide all the best quality , best service.

(6) If our our products ave any problem that we caused, they will be sent free in the next order.

(2) Experienced staffs to answer all your enquires in fluent English.

(3) We makethe OEM and ODM service for more than 6 years. And the Paypal accepted,

(4) Protection of your sales area, ideas of design and all your private information.

(5) No matter big order or small order , we will provide all the best quality , best service.

(6) If our our products ave any problem that we caused, they will be sent free in the next order.

After-sale service:

1. We will replace the broken parts with new parts in the next in the next order

2. Choose the cheapest and safest shipping agent company

3. Track the order until you get the goods

4. Welcome any feedback and advice for our products.

2. Choose the cheapest and safest shipping agent company

3. Track the order until you get the goods

4. Welcome any feedback and advice for our products.