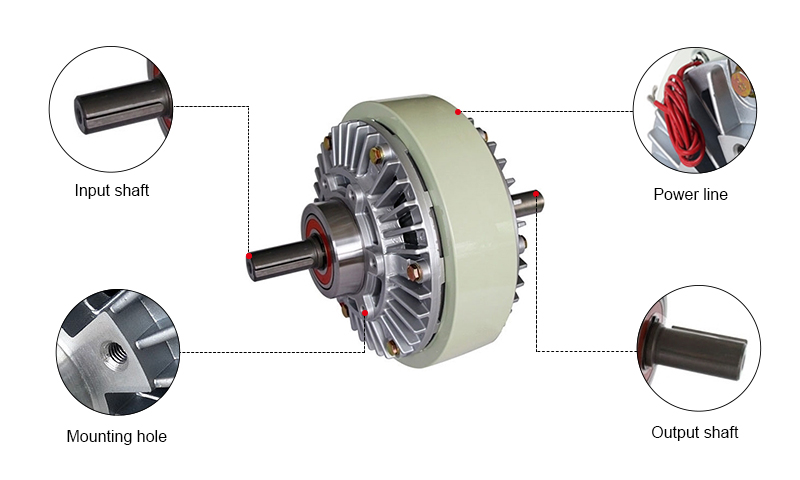

Magnetic particle clutch, max ratational speed 1800rpm, rated torque 6Nm, 15Nm, 100Nm, 200Nm are optional, 24VDC, double shaft. Magnetic powder clutch can be also used in buffering start.

DC 24V Magnetic Particle Clutch Features

1. The excitation current is linear with the torque. The transmitted torque is substantially linear with the excitation current. As long as the magnitude of the stimulation current is changed, the magnitude of the torque can be controlled over a wide range. In general, the stimulus current is substantially proportional to the transmitted torque in the range of 5%-100% of the rated torque.

2. Stable slip torque. When the stimulation current remains unchanged, the transmitted torque is not affected by the difference in rotational speed between the active and the driven, that is, there is no difference between the static friction torque and the dynamic friction torque, so that the torque can be stably achieved. This feature is applied to the tension control, and the user can accurately control the torque by adjusting the stimulation current, thereby effectively controlling the tension of the roll.

3. Prevent heat generation due to slip. Generally, the friction part is inevitably heated or even burned when continuously sliding. However, the ATO magnetic powder clutch has a complete heat sink, which will not be too hot for a long time and has a long service life.

Magnetic Particle Clutch Specification:

| Model | ATO-PC-003 | ATO-PC-006 | ATO-PC-015 | ATO-PC-025 | ATO-PC-050 | ATO-PC-100 | ATO-PC-200 | ATO-PC-400 | |

| Rated Torque | 3Nm | 6Nm | 15Nm | 25Nm | 50Nm | 100Nm | 200Nm | 400Nm | |

| Rated Current | 0.53A | 0.81A | 0.94A | 1.24A | 2.15A | 2.4A | 2.7A | 3.5A | |

| Rated Voltage | DC24V | ||||||||

| Power | 12.7W | 19.4W | 22.5W | 30W | 51.5W | 57.6W | 64.8W | 84W | |

| No. of Hour Set | 0.08S | 0.08S | 0.1S | 0.12S | 0.13S | 0.25S | 0.37S | 0.4S | |

| Moment of Interial | Input Side | 5.40*10-4 Kgcm2 | 7.30*10-4 Kgcm2 | 1.34*10-3 Kgcm2 | 3.8*10-3 Kgcm2 | 9.5*10-3 Kgcm2 | 3.5*10-2 Kgcm2 | 9.15*10-2 Kgcm2 | 2.4*10-1 Kgcm2 |

| Onput Side | 2.01*10-4 Kgcm2 | 2.40*10-4 Kgcm2 | 4.90*10-4 Kgcm2 | 4.8*10-3 Kgcm2 | 4.8*10-3 Kgcm2 | 2.5*10-2 Kgcm2 | 6.89*10-2 Kgcm2 | 2.2*10-1 Kgcm2 | |

| Air Pressure | / | 3*104 Pa | 3*104 Pa | 5*104 Pa | 1*105 Pa | 6*104 Pa | 5*104 Pa | 2*105 Pa | |

| Air Volume | / | 0.2m³/min | 0.2m³/min | 0.4m³/min | 0.6m³/min | 1.1m³/min | 1.6m³/min | 2.0m³/min | |

| Slip Power | / | 110W | 250W | 380W | 700W | 1100W | 1900W | 2800W | |

| Weight | 2.5kg | 2.7kg | 5.2kg | 9kg | 14.5kg | 37kg | 53kg | 100kg | |

| Maximum Speed | 1800 r/min | ||||||||

| Weight of powder | 7.5g | 10g | 20g | 33g | 60g | 140g | 225g | 370g | |

Details

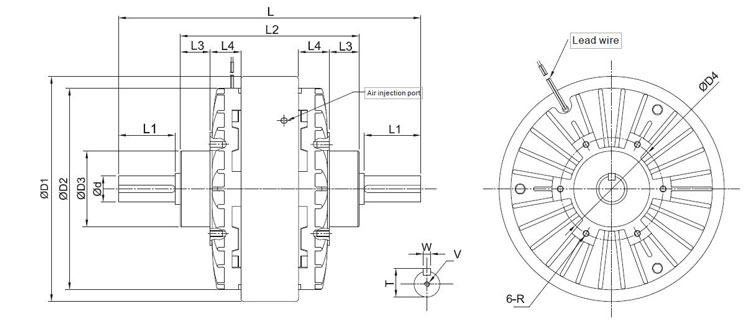

Double Shaft Magnetic Particle Clutch Dimension (unit: mm)

| Model | ATO-PC-003 | ATO-PC-006 | ATO-PC-015 | ATO-PC-025 | ATO-PC-050 | ATO-PC-100 | ATO-PC-200 | ATO-PC-400 |

| D1 | 134 | 125 | 152 | 182 | 219 | 278 | 327 | 395 |

| D2 | 75 | 110 | 126 | 160 | 196 | 260 | 301 | 365 |

| D3 (g7) | 42 | 42 | 42 | 55 | 74 | 100 | 110 | 130 |

| D4 | 64 | 64 | 64 | 78 | 100 | 140 | 150 | 200 |

| L | 164 | 154 | 192 | 230 | 294 | 360 | 408 | 500 |

| L1 | 26 | 25 | 29 | 43 | 55 | 65 | 69 | 92 |

| L2 | 100 | 95 | 124 | 136 | 172 | 216 | 250 | 291 |

| L3 | 11 | 11 | 15 | 17 | 30 | 28 | 30 | 35 |

| L4 | 14 | 17 | 25.5 | 26 | 28 | 46 | 56 | 70 |

| d (h7) | 12 | 12 | 15 | 20 | 25 | 30 | 35 | 45 |

| T (-0-0.2) | 11.5 | 13.5 | 17 | 22 | 28 | 33 | 38.5 | 48.5 |

| W (P7) | 4 | 5 | 7 | 10 | 12 | |||

| V | M3*0.6P*6L | M4*0.7P*8L | M6*1P*12L | M10*1.5P*20L | ||||

| R | 6-M5*0.8P*10L | 6-M6*1P*10L | 6-M10*1.5P*20L | 8-M10*1.5P*15L | ||||

| S | / | 1/8 | 1/4 | 3/8 | ||||

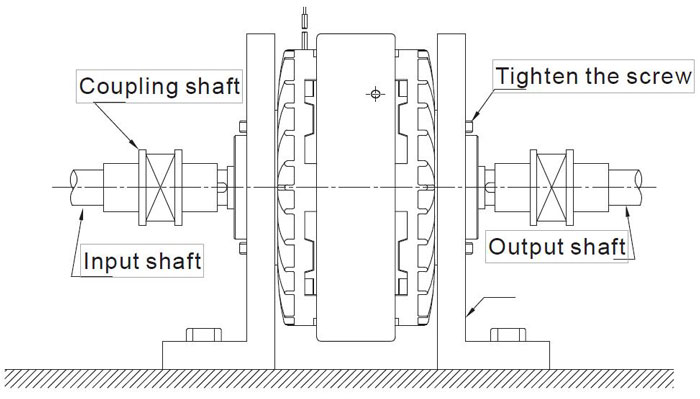

3Nm-400Nm Magnetic Powder Clutch Installation

Tips: How Magnetic Particle Clutch Work?

Magnetic powder clutch, also known as electromagnetic powder clutch, is based on electromagnetic principle and uses magnetic powder to transmit torque. The coil stationary magnetic powder clutch and the magnetic powder brake are automatic devices that control the input current to change the output transition. When the coil is not energized, the input shaft rotates, and the magnetic powder is pressed against the inner wall of the clamp ring by the centrifugal force, and the output shaft is not in contact with the input shaft. At this time, it is in an idling state. When the coil is energized, the magnetic powder generates a magnetic flux under the action of the magnetic force line, so that the output shaft and the input shaft become a rigid body and rotate, and a slip occurs when the overload occurs, and the working state is at this time. Thereby achieving the purpose of transmitting torque.

Application case:

1. Packing and wrapping systems: packing machine, strapping machines, wrapping machinery.

2. Textile machinery: fiber twisters, treatment machines, weaving machines.

3. Metal fishing systems: extruders, wire stretchers, presses, welders, steel wire retractors, cutters, pipe makers, wire winding machines.

4. Machine tool systems: lathes.

5. Millers, steel extruders, CNC lathes, specialized machinery.

6. Transportation equipment: hoists, feeders, conveyors, rollers, winders.

7. Paper- making systems: bag-making machines, box-making machines, slitters, book-making machinery, cutters, copy paper machines.

8. Printing systems: conveyors and in-feeders.

9. Wood-working systems: saws, wood-working machine, laminators.

10. Office equipment: electronic copy machines, calculators, fax machines, coin counters, printers.

11. Testing systems: lab machines, durability testers, measuring systems.

12. Food processing systems: meat cutting machines, cookie making machines, canning machines, noodle making machines.

13. Others: speed reducers, electroplating machinery, physics and chemistry machines, paper-making machines, pulp processing

machines.

Using Taiwan professional production technology and advanced production equipment, professional production of face mask,face mask machine,Air expanding shaft(key type),Air expanding shaft(friction),Air expanding shaft(leaf type),shaft parts,aluminum roller

with rotation shaft,aluminum roller with rotation shaft,aluminum roller without shaft,aluminum roller with stripe,safey chucks(flange type),safety chuk(slip type),safety chuk(pedeatal type),Electromagnetic Clutch,Air cluth,Air brake,Tension detector,EPC Edge Position Control,CPC Center position control,Tension detector,Automatic tension controller,Manual tension controller,Semi-Auto tension controller,Powder,Powder cluth,Powder brake,Electromagnetic clutch,Electromagnetic brake,etc.

Miraculously zhele Electromechanical, leading a few microns fine circles.

Our Services & Strength

Eight reasons to choose us:

1. Perfect service system and after-sale protection.

2. Quality problems will be solved within 24 hours.

3. One-to-one customer service tracking processing.

4. Companies carry out the ERP management, improve enterprise fast response.

5. Quality assurance, one year warranty.

6. Supporting professional matched other equipment.

7. The company has more than one product testing units, the implementation of ISO9001: 2015.

8. Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell your email, so that we can regard your inquiry priority.2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmission parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30 days.

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.More concerned for our products , please do not hesitate to inquiry now!