| Roll Width: | 1100mm | Unwind Diameter: | ∅1000 |

|---|---|---|---|

| Winding Diameter: | ∅600 | Cutting Thickness: | 20g-300g/㎡ |

| Slitting Speed: | 10-200m/min | Cutting Accuracy: | 0.5mm |

| Splitting Method: | Round Or Straight Knife | Retrieving And Unwinding Scroll: | Air Shaft |

| Material Discharge Method: | Blow Air To Remove Waste Materials | Power: | 5KW |

| Machine Dimensions (length) × Wide × High: | 2400×2500×1500(mm) | INPUT VOLTAGE: | 380V 50HZ |

| Highlight: |

1100 Type Horizontal Slitting Machine, 200m/min Horizontal Slitting Machine, kraft paper rewinding and slitting machine |

||

1100 type kraft paper slitting and rewinding machine horizontal slitting machine

Use To:

This machine is suitable for cutting and rewinding various types of roll materials. Cutting and rewinding of roll materials such as self-adhesive materials, film PVC, PET, release film, breathable film, pearl film, various types of paper with a weight of 50-300g/㎡ (copperplate paper, double tape paper, coated paper, white cardboard, silicone oil paper, etc.), non-woven fabric, etc

Performance and characteristics:

1. The main control system PLC+human-machine interface has fully automatic control of taper tension, and the control screen is easy to operate

2. Magnetic powder tension control for winding and unwinding

3. Automatic meter counting, unwinding photoelectric correction, alarm and other functions

4. Equipped with a waste material fan for conveying

5. Double expansion axis winding

Introduction to Machine Parameters (can be professionally customized according to your needs)

| Roll width | 1100mm |

| Unwind Diameter | ∅600 |

| winding diameter | ∅450 |

| Cutting thickness | 20g-300g/㎡ |

| Slitting Speed | 10-200m/min |

| Cutting accuracy | ±0.5mm |

| Splitting method | Round or straight knife |

| Retrieving and unwinding scroll | air shaft |

| Material discharge method | Blow air to remove waste edges |

| power | 4KW |

| Machine dimensions (length) × wide × High | 1500×2500×1500(mm) |

| INPUT VOLTAGE | 380V 50HZ |

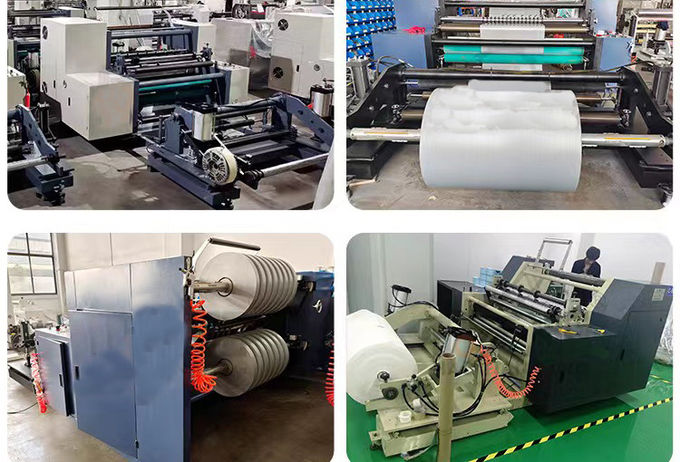

Product real shot display

Product cutting materials

WHY CHOOSE US:

1. We have over 15 years of experience

2. We are a manufacturer exporting to over 15 countries

3. Strong production capacity to ensure timely delivery

4. We guarantee product quality and pre-sales and after-sales service

Packaging and Transportation

Packaging details: packed with pearl cotton and plastic film, some items are packed in wooden boxes

Delivery time: Within 30-60 days after payment

Frequently asked Question

Q 1: Where is your factory located? How can I get there?

Answer: Our factory is located in Wenzhou, Zhejiang Province, China. The nearest airport is Wenzhou Airport, and we can pick you up at the airport

40 minutes by plane from Shanghai and 4 hours by train

It takes 2 hours by plane from Guangzhou

Q 2: Does your company provide installation services for foreign machines

Answer: We have a strong service team that can provide foreign installation services and engineer training services for all machines purchased from our company. But the buyer needs to provide airfare, food, hotel expenses, etc

Q3: How does your company provide after-sales service

Answer: The warranty period for all machines purchased from our company is one year (excluding any human error). Lifetime maintenance and 24-hour hotline